Graphene filters reaching industrial grade

Australian engineers have unveiled a new type of graphene-based filter that work several times faster than current equivalents.

Australian engineers have unveiled a new type of graphene-based filter that work several times faster than current equivalents.

In what could be the key to managing the global water crisis, the filter developed by Monash University and the University of Kentucky filters water and other liquids nine times faster than the current leading commercial filter.

It can even be produced on an industrial scale.

Lack of access to safe, clean water is a growing risk around the world, but help could be on the way.

The new graphene filter is strong and stable enough to be used for extended periods in harsh, corrosive environments, and with less maintenance than other filters on the market.

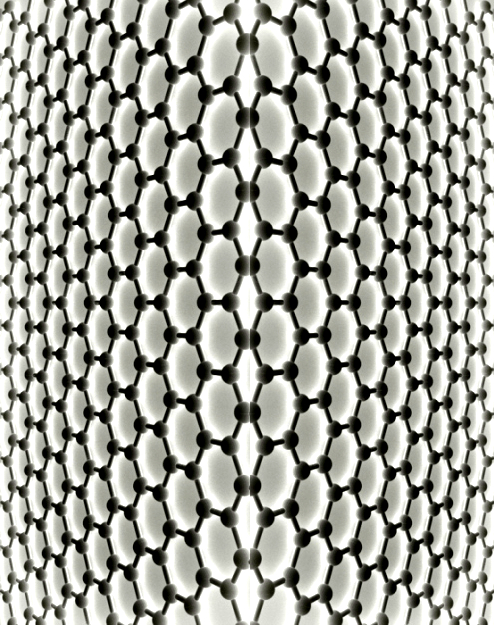

The key to the new filter was developing a viscous form of graphene oxide that could be spread very thinly with a blade.

“This technique creates a uniform arrangement in the graphene, and that evenness gives our filter special properties,” Associate Professor Mainak Majumder from Monash University said.

This technique allows the filters to be produced much faster and in larger sizes, which is critical for developing commercial applications.

The graphene-based filter could be used to filter chemicals, viruses, or bacteria from a range of liquids, purify water, dairy products or wine, or in the production of pharmaceuticals.

It can filter out anything bigger than one nanometre, which is about 100,000 times smaller than the width of a human hair.

This is the first time that a graphene filter has been able to be produced on an industrial scale – a problem that has plagued the scientific community for years.

“It’s been a race to see who could develop this technology first, because until now graphene-based filters could only be used on a small scale in the lab,” said research team member and PhD candidate, Abozar Akbari.

The team’s research was supported by industry partner Ionic Industries, as well as a number of Australian Research Council grants.

Ionic Industries’ CEO, Mark Muzzin, sats the next step is to get the patented graphene-based filter on the market.

“We are currently developing ways to test how the filter fares against particular contaminants that are of interest to our customers” Mr Muzzin said.

More details are available in the full report, here.

Print

Print